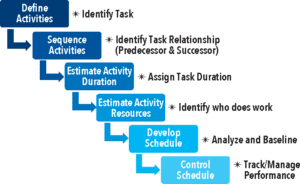

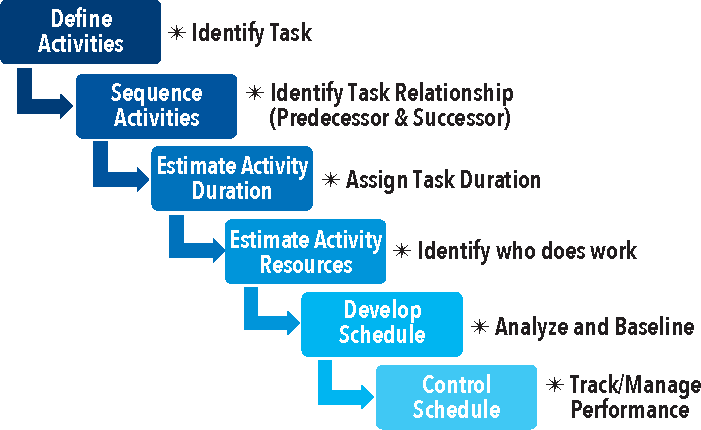

Schedule management is easy to implement when it’s done right, otherwise get ready to do multiple re-baselines. The process is similar wherever you look, including NASA schedule management guidelines, DoD Program life cycle guidelines, or Project Management Institute. Figure 1 illustrates the six steps: define activities, sequence activities, estimate activity duration and resources, develop schedule, and control schedule.

Schedule management is easy to implement when it’s done right, otherwise get ready to do multiple re-baselines. The process is similar wherever you look, including NASA schedule management guidelines, DoD Program life cycle guidelines, or Project Management Institute. Figure 1 illustrates the six steps: define activities, sequence activities, estimate activity duration and resources, develop schedule, and control schedule.

“The purpose of schedule management is to provide the framework for time-phasing, resource planning, coordination, and communicating the necessary tasks within a work effort.” NASA Schedule Management Handbook

In practice schedule is usually developed using Microsoft Project; however, it can be done in Excel depending on the size of the project. Understanding the concepts of scheduling is critical and can be done successfully in Excel if it is implemented correctly. (I would recommend Microsoft Project to take advantage of built in capabilities to easily develop and control schedules.)

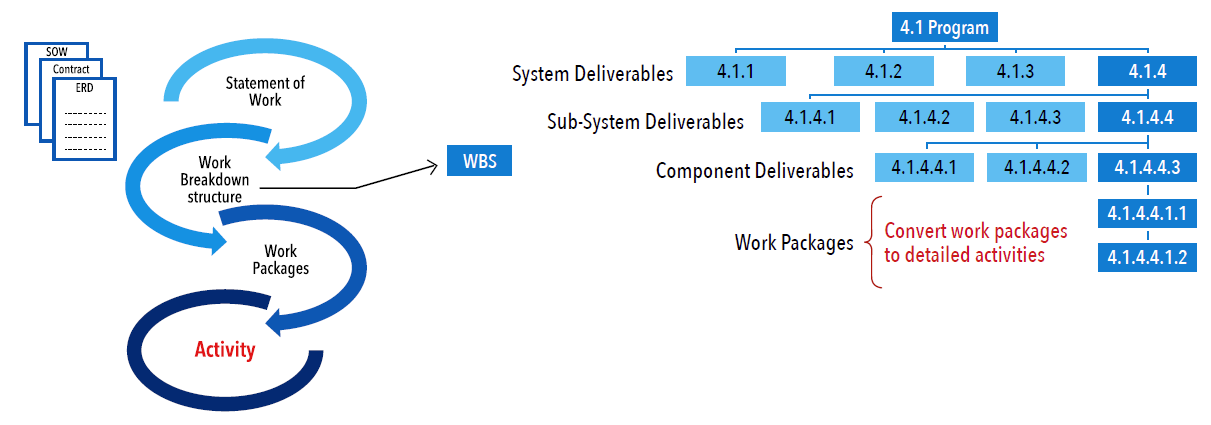

Step 1: Define activities means identifying tasks. Of all the six steps this is the most critical step and worth spending time to understand what the customer really wants and when the product or services are required. Usually as a project manager when contract is given to you, you have better understanding of what needs to be delivered and you are working with your team to tailor out the detail activities. However, I would recommend to start with contract/statement of work then break down the deliverables using Work Breakdown Structure (WBS) process and identify detail activities through work packages. Work breakdown structure divides project Statement of Work to manageable activities, making it easier to supervise and estimate see Figure 2

Step 1: Define activities means identifying tasks. Of all the six steps this is the most critical step and worth spending time to understand what the customer really wants and when the product or services are required. Usually as a project manager when contract is given to you, you have better understanding of what needs to be delivered and you are working with your team to tailor out the detail activities. However, I would recommend to start with contract/statement of work then break down the deliverables using Work Breakdown Structure (WBS) process and identify detail activities through work packages. Work breakdown structure divides project Statement of Work to manageable activities, making it easier to supervise and estimate see Figure 2

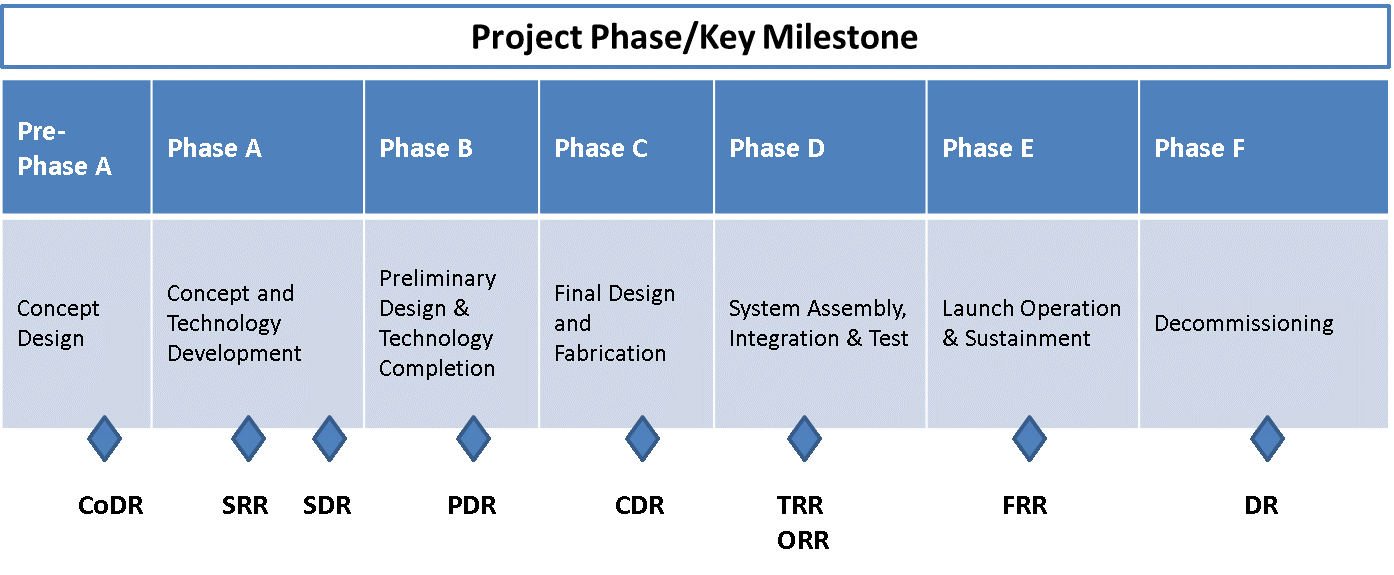

Key project milestone can also help with identifying activities and timeframe. Depending on current phase of your project, you can detail out next 6 to 12 months of schedule activities in Rolling Wave Plan and rest in planning package. Rolling Wave Plan is where near term work is planned in detail and distant work is kept at a higher level. Planning package includes scope to be completed but no activities. Keep in mind near-term typically implies 6 to 12 months from the current date.

Key project milestone can also help with identifying activities and timeframe. Depending on current phase of your project, you can detail out next 6 to 12 months of schedule activities in Rolling Wave Plan and rest in planning package. Rolling Wave Plan is where near term work is planned in detail and distant work is kept at a higher level. Planning package includes scope to be completed but no activities. Keep in mind near-term typically implies 6 to 12 months from the current date.

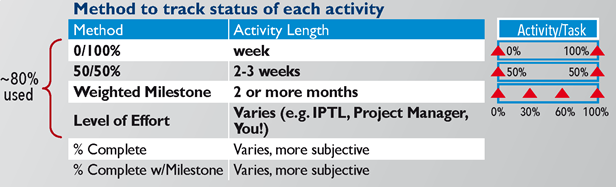

Once the activities are identified consider time frame for each activity to track earned value. You don’t want to identify one activity that will take 6 months or more, it will be hard to measure progress of that particular task. Level of details is needed to analyze if you are behind, ahead, or on schedule. If activity is one week or less, then consider 0/100% method. See Figure 3 for other possible methods track status. Also, estimating duration of activity explained in details in step3. Earned Value Management Systems article.

Once the activities are identified consider time frame for each activity to track earned value. You don’t want to identify one activity that will take 6 months or more, it will be hard to measure progress of that particular task. Level of details is needed to analyze if you are behind, ahead, or on schedule. If activity is one week or less, then consider 0/100% method. See Figure 3 for other possible methods track status. Also, estimating duration of activity explained in details in step3. Earned Value Management Systems article.

Summary of step 1. Identify activity through work breakdown structure and define timeframe using earned value method to track status.

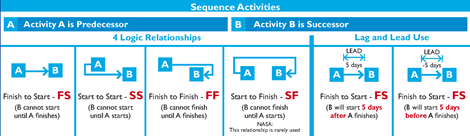

Step2: sequence activities – identify task relationship. I cannot explain any simpler then in the figure below.